Get ready to be amazed by some of Grandma’s never-before-seen tricks for unlocking the full potential of your wood-fired oven! Discover well-kept secrets on how to get to know and use your oven better, and become a true wood-fired cooking expert.

Read moreOur rotary wood ovens for bakeries

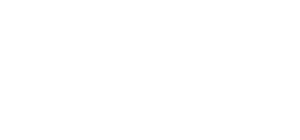

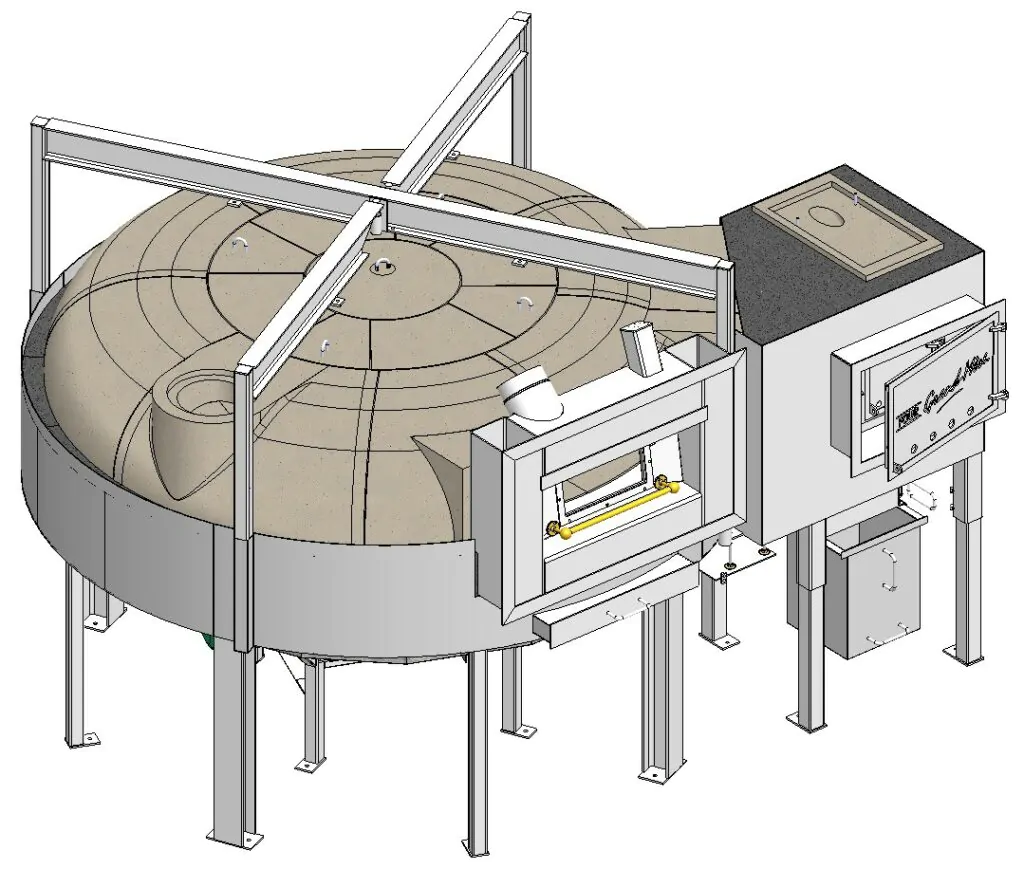

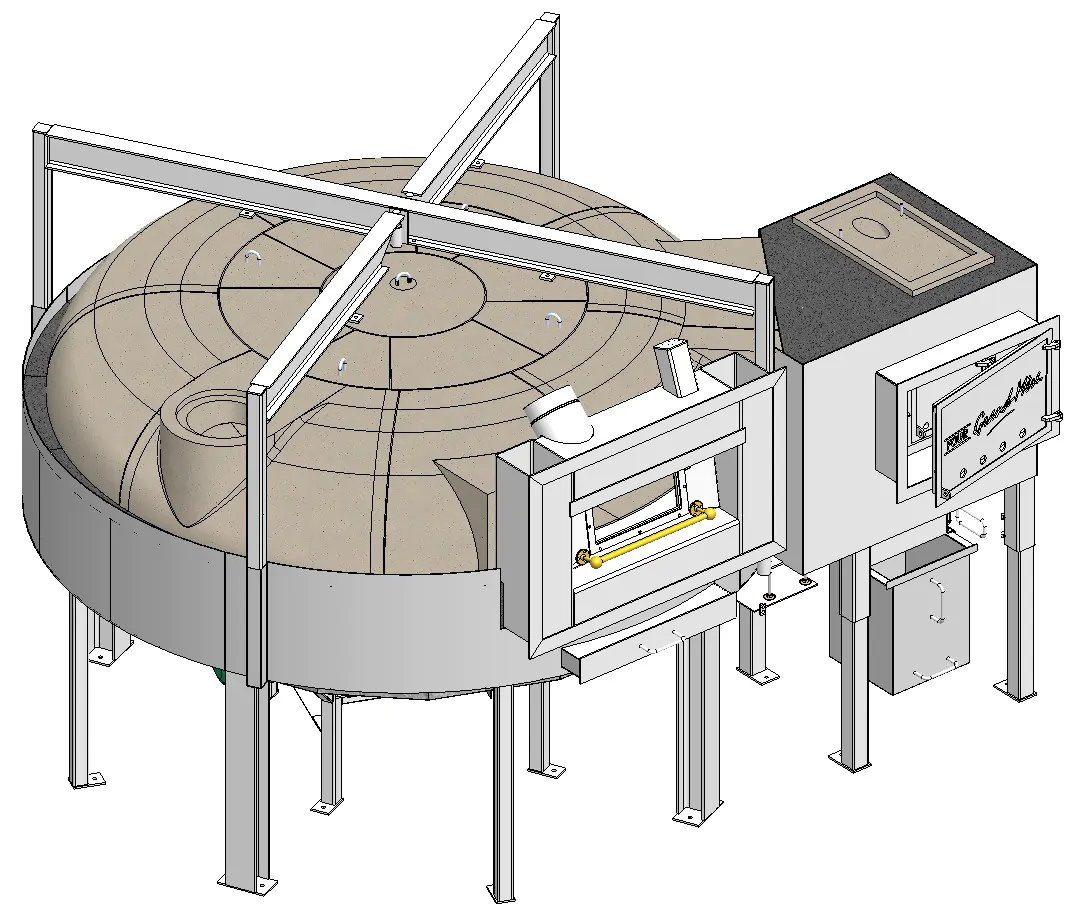

Designed for the most demanding bakers, our rotating floor ovens for bread offer the perfect combination of taste, baking quality and maximum productivity.

These side throat ovens are distinguished by their rotating floor, which is driven by

an electric motor under the floor.

The resources of modern technology used in wood-fired cooking

Our wood ovens with rotating floor are with direct heating. They provide all the advantages of traditional wood-fired cooking, while ensuring excellent productivity and increased working comfort.

A perfectly controlled bread baking

As with all our side hearth bread ovens, you can do a series of baking processes or simply reheat between two batches.

In reality, the main difference hides beneath the baking chamber. A central shaft powered by an electric motor makes the floor rotate forwards and backwards, ensuring the entire floor is uniformly heated during the heating stage, and then during the baking stage.

So, when the different areas of the vault are not exactly at the same temperature, the baking always remains homogeneous, as the breads pass through all the areas at the same speed.

When putting or removing the dough from the oven, the baker can move this motorised floor forwards or backwards at the desired speed. Thanks to the control panel joystick, he can stop or make the floor rotate forwards or backwards, with a simple gesture and high precision.

Clearly more efficient baking capacities

As the whole floor can be used, our rotating bread ovens offer clearly higher production capacities than a static floor oven.

For example, if you decide to put baguettes in the oven, you can bake 7.58kg of dough per hour and per m2 in our rotary ovens, as opposed to 5.60kg in our fixed deck oven models, which means a surplus of capacity of around 35%!

Up to 2 steam systems for a perfect baking

Our rotary floor ovens for bread are equipped with 1 or 2 steamers to allow the bread to rise better, ensuring a crispy crust and a light and airy crumb. Below are the two systems in question:

- 1 or 2 passive steam systems linked to the oven’s 20kg steel jwalls.

- 1 electric steam cannon that transforms water into steam, supplied by a solenoid valve (only available for the R 3000 FL).

Ready to arouse your customers’ appetites? All you have to do is press a button on the control panel to start the steam extractor linked to a fan, and send a delightful smell of bread into your shop or to the street!

Our different models

Our range of rotating floor ovens for bread

Our 3 rotating ovens are made with a chamotte vault. The side firebox can be mounted on the right or left according to the configuration of your oven.

Rotating floor ovens

Side firebox with a throat oven with an electrically rotating floor. A premium oven for perfectly uniform bread baking.

FBOULR2000FL

FBOULR2000FL

|

FBOULR2500FL

FBOULR2500FL

|

FBOULR3000FL

FBOULR3000FL

|

|

|---|---|---|---|

| Surface area of sole (m²) | 3,14 | 4,9 | 7 |

| External dimensions D x W x H (m) | 2,36 × 2,77 × 2,27 | 2,89 × 3,31 × 2,10 | 3,72 × 3,60 × 2,29 |

| Power (kW) | 120 | 180 | 235 |

| Baguettes per batch | 50 | 78 | 112 |

| Number of 500 g loaves per batch | 35 | 54 | 77 |

| See the product | See the product | See the product |

Supplies and equipment included

This insulated steel door also comprises a glass section and lighting for the baking chamber.

options

Embellished with beautiful ears of wheat, this cast-iron door features an automatic closing system, so that the baker can open and close it with his peel.

You can also use a handle with a counterweight to manipulate it in a more traditional, effortless way.

We reworked the original model in our workshops to integrate a glass section and a lamp in order to illuminate the baking chamber.